PLEase Call Me !

+91 90990 85037

Secure Your Reverse Flow

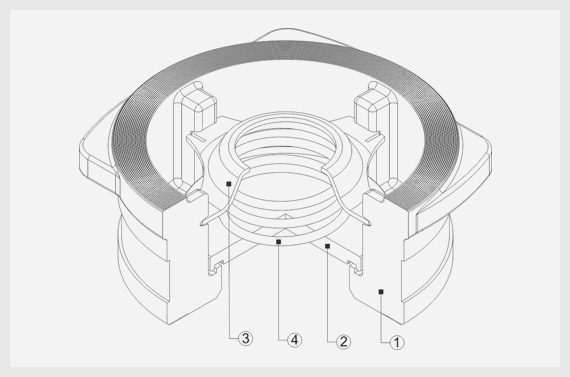

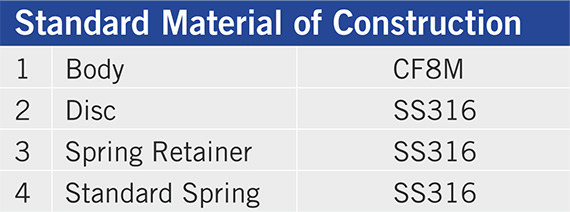

Disc Check Valve

GMFPL Stainless Steel Disc-Check Valves are of wafer type design to be sandwiched between flanges. These valves provide a compact installation when compared to the conventional flanged end check valves. It is suitable for use on a wide range of fluids for applications in process lines, hot water systems, steam and condensate lines etc. Its applications are in various types of Industries such as: Chemical, Pharmaceutical, Power Generation, Textile, Water Treatment, Boilers, Breweries, etc. They have an increased gasket face area.

Note: Disc Check Valves are not suitable for use in pulp lines and also where heavily pulsating flow exists, such as close to a compressor.

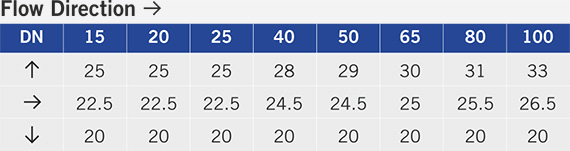

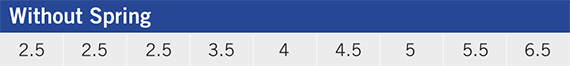

Opening Pressures in mbar

Differential pressures with zero flow for standard spring.

Where lowest opening pressures are required, valves without springs can be installed in vertical pipes with bottom -to- top flow.

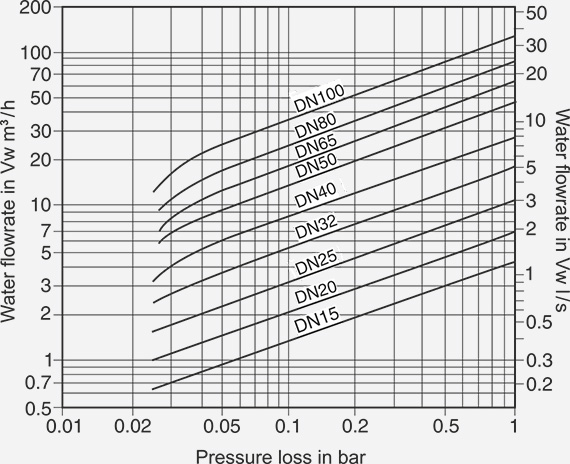

Pressure Loss Diagram

Differential pressures with zero flow for standard spring.

Pressure loss diagram with open valve at 20°C. The values indicated are applicable to spring loaded valves with horizontal flow. With vertical flow, insignificant deviations occur only within the range of partial opening. The curves given in the chart are valid for water at 20°C.

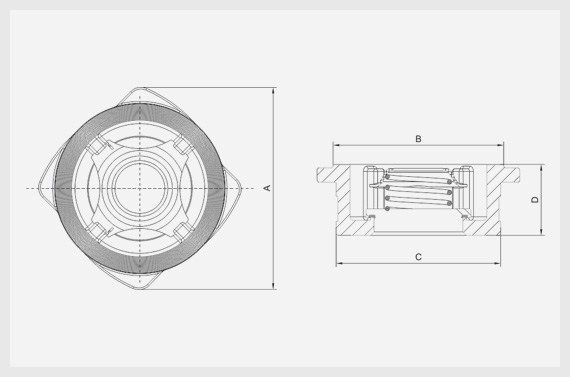

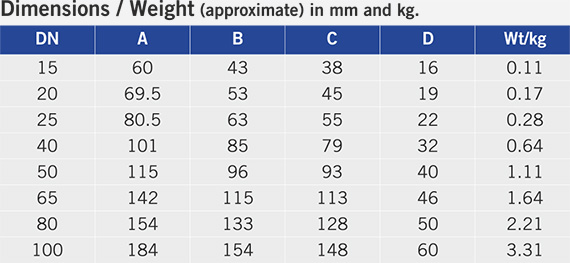

Size and Pipe Connections

DN15, DN20, DN25, DN40, DN50, DN65, DN80, DN100

suitable for installation between the following flanges:

BS: 10 Table 'E' and 'H',

BS: 4504/ DIN: PN6, PN10, PN16, PN25, PN 40;

JIS: JIS5, JIS10, JIS16, JIS20

ASME B16.5: 150# and 300#

Operation

Disc Check Valves are opened by the pressure of the fluid and closed by the spring as soon as the flow ceases and before the reverse flow occurs.

Standards

Designed and Manufactured in accordance with BS 7438.